Is a rolling tool bag suitable for use on construction sites or in outdoor environments?

Structural Features that Define the Outdoor Suitability of a Rolling Tool Bag

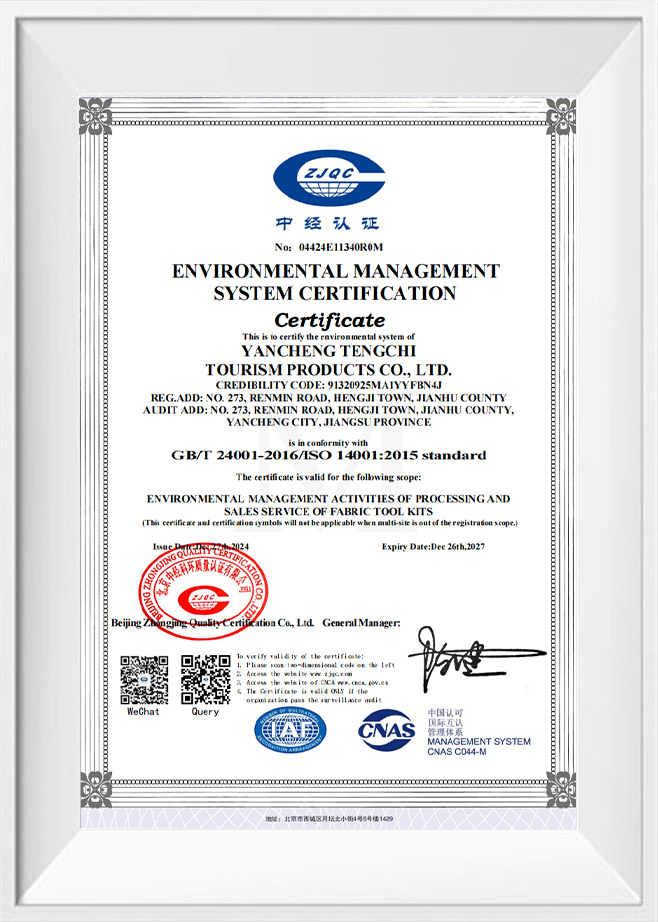

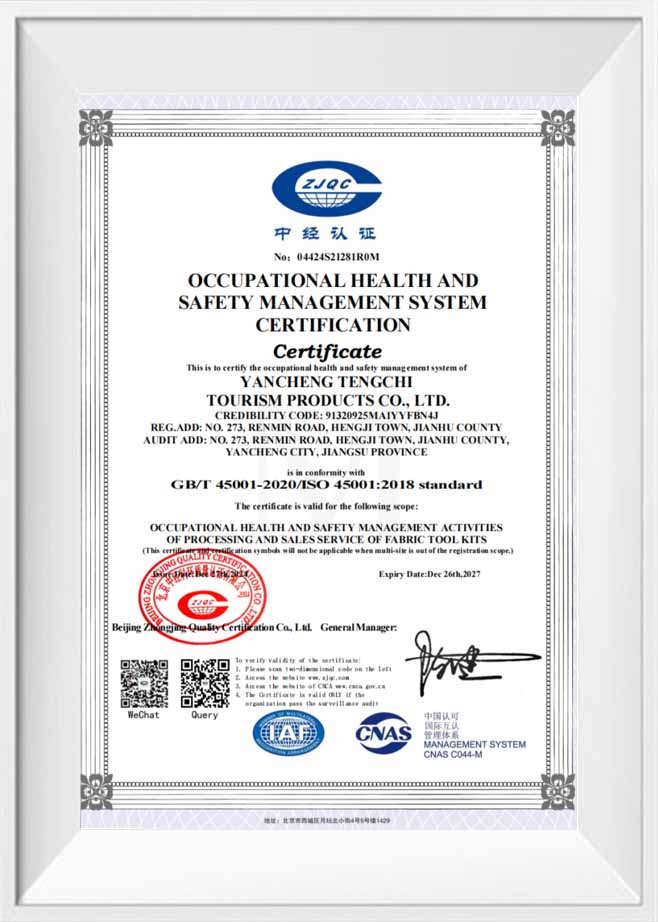

A rolling tool bag achieves its outdoor adaptability through a combination of reinforced fabric, molded structural components, and a trolley system designed to withstand long-term mobility. For manufacturers such as Tengchi, which focus on producing professional-grade tool bags for technicians, electricians, and field maintenance workers, structural integrity is an essential design consideration. The framework typically integrates a rigid bottom panel, reinforced corners, and multi-layer fabric construction to maintain shape and prevent deformation even when heavily loaded. These characteristics support its use on construction sites where uneven, dusty, or abrasive surfaces are common. The rolling mechanism complements the structural strength, allowing the user to transport heavy tools with reduced physical strain while maintaining stability.

Advantages of the Trolley System in Construction and Outdoor Settings

A significant advantage of a rolling tool bag lies in the trolley system equipped with 360-degree swivel wheels. This feature enhances mobility in complex environments, including concrete floors, parking lots, pathways, and partially finished construction surfaces. Workers frequently need to move between indoor and outdoor areas while carrying tools of varying sizes and weights. The trolley system reduces lifting pressure, particularly during long-distance movement. Tengchi incorporates robust handles and wheel housings to ensure that the structure remains stable in field environments where debris or small obstacles may impede smooth rolling. While extremely rough terrain may still limit mobility, the system provides substantial support for most standard construction and outdoor work surfaces.

Material Selection and Durability in Outdoor Environments

The ability of a rolling tool bag to function effectively outdoors depends significantly on the materials used in its construction. Tengchi selects high-strength fabrics, abrasion-resistant panels, and reinforced stitching to extend product longevity. These materials allow the bag to endure friction from concrete, gravel, or metal platforms without premature wear. Moisture exposure is also a common challenge for outdoor technicians. Although rolling tool bags are not typically designed for full water immersion, the dense fabric and treated outer layers provide resistance to moisture and light rain. The combination of structural fabric and protective bottom molding prevents tools from being exposed to damp ground surfaces commonly found on construction sites.

Stability and Load-Bearing Performance on Uneven Surfaces

Construction sites often feature uneven ground conditions, including slopes, debris, and unfinished pavements. A rolling tool bag must therefore provide stability both when stationary and in motion. The reinforced base and weight-balanced internal structure help prevent tipping. Tengchi designs its trolley tool bags with a wide wheelbase to distribute weight effectively, allowing the bag to remain upright even when placed on gravel or slightly sloped surfaces. The load-bearing capability is further supported by internal compartments that separate heavy tools such as drills, wrenches, and testing equipment. This prevents internal shifting during movement and reduces the risk of instability when navigating outdoor terrain.

Organizational Benefits in Fast-Paced Construction Settings

A rolling tool bag is particularly useful on construction sites due to its ability to store and organize various tools in designated compartments. Professionals working in electrical installation, HVAC systems, or mechanical assembly require quick access to both manual and power tools. The interior of such bags usually includes pockets, dividers, elastic straps, and large compartments for bulky equipment. Tengchi emphasizes structured organization in its product line, allowing workers to access their tools efficiently without excessive searching. This becomes important in outdoor environments where lighting may vary, surfaces may be dusty, and workers need to maintain focus while minimizing downtime.

Environmental Performance Across Construction and Outdoor Conditions

The table below summarizes how a rolling tool bag typically performs under different outdoor or construction site conditions:

| Environmental Condition |

Typical Challenge |

Rolling Tool Bag Performance |

| Dusty construction sites |

Abrasion and equipment contamination |

High-strength fabrics resist friction and protect tools |

| Wet surfaces or morning dew |

Moisture exposure |

Molded bottom and treated fabrics reduce water infiltration |

| Uneven ground |

Tipping or instability |

Reinforced base and wide wheel span provide balance |

| Long walking distances |

Worker fatigue |

Trolley system minimizes physical carrying effort |

| Areas with small debris |

Wheel obstruction |

360-degree wheels navigate moderate debris effectively |

Suitability for Electricians, Maintenance Engineers, and Construction Workers

Rolling tool bags are highly relevant to the work patterns of electricians, installers, and mechanical repair personnel. These professionals often carry a large assortment of tools, testing instruments, electrical components, and safety accessories. Tengchi’s manufacturing approach emphasizes the combination of load capacity, structured organization, and ergonomic design, making the rolling tool bag a practical choice for long-term outdoor applications. Electricians benefit from the ability to transport heavy coil meters, crimping tools, and cable testers with minimal strain. Maintenance engineers working in industrial facilities can move between work zones carrying necessary equipment. For construction workers, the bag serves as a mobile storage unit that adapts to different stages of project development.

Wheel and Handle Design Considerations for Outdoor Durability

The wheel system and telescopic handle are essential components that influence outdoor usability. Wheels must be strong enough to handle weight while maintaining smooth movement across semi-rough surfaces. Tengchi incorporates reinforced wheel housings that provide structural support, while swivel capabilities allow workers to navigate tight spaces or change direction easily. The telescopic handle is usually made from metal tubing capable of withstanding repeated extension and retraction. Its ergonomic grip allows users to maintain control even when navigating slight slopes or uneven paths. These features collectively support long-term use during fieldwork and construction activities.

Maintenance and Cleaning Requirements in Outdoor Environments

After use on construction sites or outdoor work areas, a rolling tool bag will require cleaning to remove dust, mud, or debris. The material selection plays an important role in simplifying this process. Tengchi’s products incorporate fabrics that can be wiped clean without absorbing dirt. The molded bottom can be rinsed if necessary, and the wheels are designed to shed dust rather than retain it. Regular maintenance ensures continued performance and reduces the risk of wheel blockage or fabric deterioration. A well-maintained rolling tool bag can withstand extended periods of outdoor service without functional decline.

Comparison of Rolling Tool Bag Features with Typical Outdoor Requirements

The following table summarizes the alignment between rolling tool bag features and essential requirements for outdoor or construction site applications:

| Required Outdoor Feature |

Rolling Tool Bag Attribute |

Practical Benefit |

| High load capacity |

Reinforced structure and molded bottom |

Supports heavy tool sets |

| Mobility across mixed surfaces |

Swivel wheels and trolley handle |

Smooth movement and reduced fatigue |

| Organization and accessibility |

Multi-layer pockets and dividers |

Faster workflow in dynamic environments |

| Durability against abrasion |

Heavy-duty outer fabric |

Longevity during exposure to rough surfaces |

| Resistance to moisture |

Sealed base and treated materials |

Protection during damp conditions |

Overall Assessment of Outdoor Suitability

A rolling tool bag meets the operational demands of construction sites and outdoor environments through its structural strength, organized interior, and mobile trolley system. When manufactured with attention to high-strength materials, reinforced stitching, and ergonomic mobility features—as in Tengchi’s product line—it provides consistent support in uneven, dusty, wet, or partially developed environments. The adaptability of the design offers convenience to professionals who require both durability and mobility in their daily work.

Adaptability in Field Conditions

Based on its material composition, structural configuration, and mobility advantages, a rolling tool bag is well-suited for use in outdoor and construction settings. Its reinforced components support stability and tool protection, while the trolley system reduces manual carrying effort. Through thoughtful design and durable materials, rolling tool bags provide a reliable storage and transportation solution for electricians, installers, maintenance personnel, and construction workers who regularly operate in demanding environments.

English

English  español

español