Product Definition and Core Features

The Rolling Tool Backpack is a professional tool storage device that integrates backpack carrying and wheeled dragging functionality, designed to meet the needs of high-frequency movement, long-distance transport, and multi-tool management. Compared to traditional toolboxes and ordinary tool backpacks, its biggest advantage lies in its ability to freely switch between "shoulder-carrying mode" and "wheeled mode," greatly improving carrying flexibility and work efficiency.

- Dual-Mode Structure: Can be carried on the shoulder or dragged. Most products are equipped with a retractable pull rod and wear-resistant wheels, allowing users to freely switch carrying methods according to work distance and tool weight. For short distances or staircase transport, it can be carried on the back; for long distances on flat ground, it can be rolled, reducing the load on the shoulders and back.

- Large Capacity and Categorized Partitions: The interior of the rolling tool backpack is typically designed with a spacious main compartment, inner and outer pockets, elastic tool loops, removable dividers, and small item storage bags, enabling efficient and modular tool management. Users can categorize hand tools, power tools, spare parts, and cables to avoid clutter and reduce tool searching time.

- Durable Materials and Structure: The outer layer uses high-density ripstop Oxford cloth (600D–1680D), PU coating, or industrial-grade canvas; the chassis is made of TPU or rubber; the wheels use PU tires or wear-resistant plastic rims, ensuring smooth rolling and long-term durability. Key stress points typically use reinforced stitching and metal rivets, resulting in high load-bearing capacity.

- Ergonomic Design: Thickened cushioning shoulder straps and a breathable back panel evenly distribute weight; the pull handle is ergonomically designed, and the wheels are smooth, suitable for long-distance transport; some high-end products also feature a thickened carrying strap for easy one-handed carrying.

- Additional Features: Waterproof zippers, dust covers, safety locks, reflective strips, LED lighting modules, Bluetooth tracking, and other features meet the safety and convenience needs of professional users in various working environments.

Main Application Scenarios

The core value of the Rolling Tool Backpack lies in **high-frequency movement and tool categorization management**. Main application scenarios include:

Electrical and Technical Repair: Electricians typically need to carry tools such as screwdrivers, pliers, test pens, wires, and small testing instruments. The rolling tool backpack allows for quick transport from the workshop to the field, flexibly switching between shoulder carrying and rolling, reducing time spent searching for and moving tools, and improving overall efficiency.

Plumbing and HVAC Maintenance: Plumbers and HVAC repair personnel need to move heavy tools, pipe wrenches, spanners, and sealing materials. The rolling function reduces carrying pressure during long-distance transport on flat ground, while internal partitions prevent small tools from becoming disorganized, improving work efficiency.

Automotive Repair and Mobile Services: Mobile automotive repair, emergency rescue, or on-site services require carrying a large number of hand tools and power tools. The rolling tool backpack can neatly store tools and quickly move them to different work areas, saving transport time and improving response speed.

Construction and On-Site Operations: Construction sites are complex environments, requiring frequent tool movement. The wear-resistant chassis, reinforced pull rods, and large capacity of the roller tool backpack make it suitable for carrying hand tools, power tools, and spare parts, balancing portability and stability.

Home DIY and Amateur Creators: Home users and makers who prioritize tool storage and portability can also use rolling tool backpacks for multi-tool management and mobile operations, making them particularly suitable for home renovations or outdoor work.

Other Extended Scenarios: Scenarios requiring frequent handling of small equipment, such as security patrols, garden maintenance, logistics sorting, and moving photography equipment, can benefit from rolling tool backpacks, improving mobility and equipment protection.

Market Status and Development Trends

The rolling tool backpack market has seen continuous growth in recent years, primarily driven by demand from the construction, electrical, plumbing, automotive repair, and mobile service industries. As professional technicians increasingly demand efficient tool management and portability, the disadvantages of traditional toolboxes or ordinary tool backpacks—such as inconvenience in handling, limited capacity, and the tendency for tools to become disorganized—have further propelled rolling tool backpacks to become the mainstream choice in the industry.

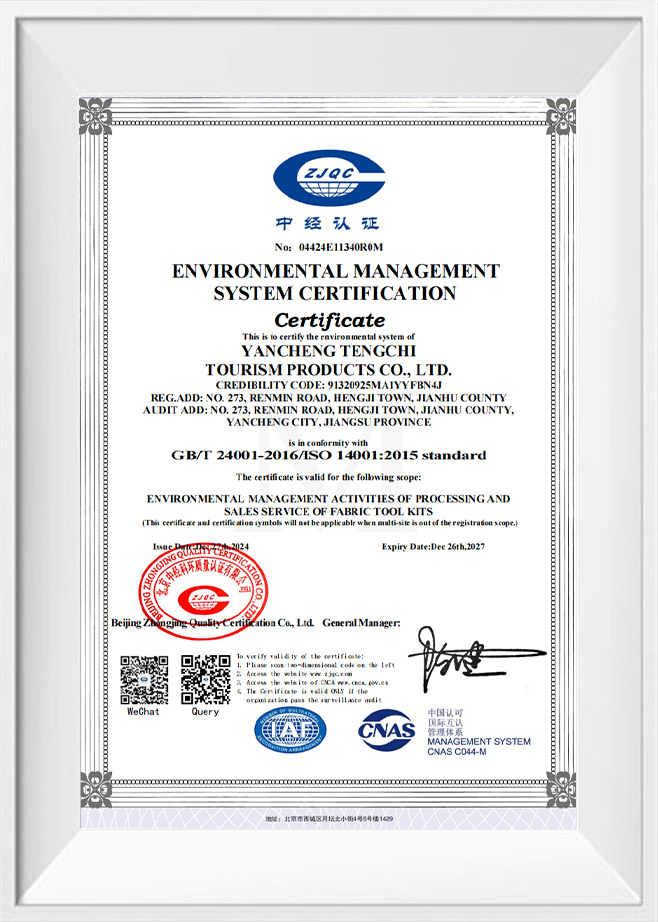

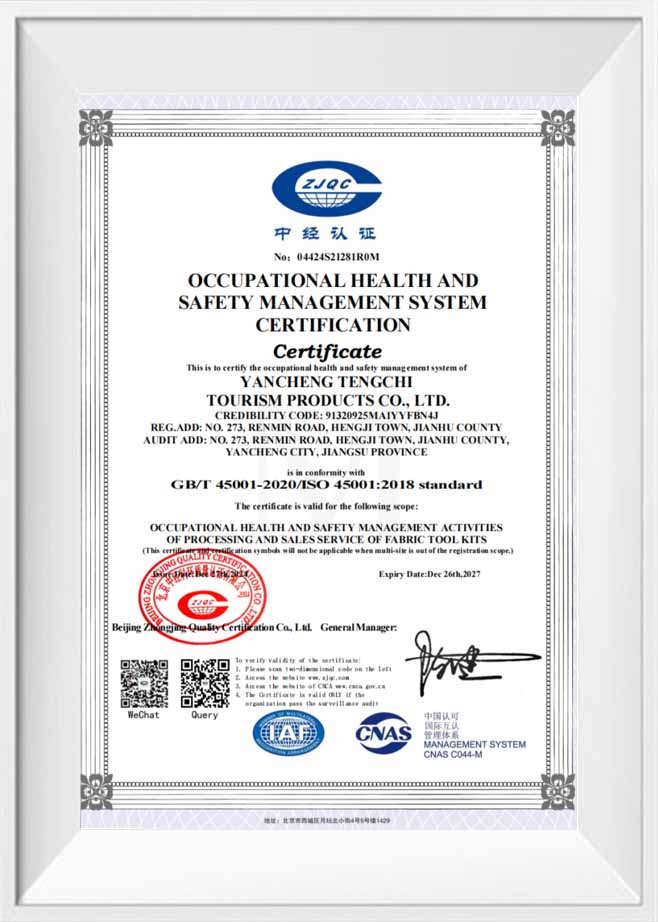

Yancheng Tengchi Tourism Products Co., Ltd. owns a 25,000-square-meter factory with four professional production lines and over 130 professional staff. This allows for rapid prototyping within 7–10 days, enabling efficient product development and delivery. Through independent control of the production process, Yancheng Tengchi Tourism Products Co., Ltd. ensures that every detail of each tool bag meets high quality standards, reflecting the company's advantages in durability, structural design, and detail optimization.

Yancheng Tengchi Tourism Products Co., Ltd. also emphasizes customized services, offering personalized rolling tool backpack designs based on clients' brand image and product characteristics. These designs include color, internal compartments, pocket layout, and additional features such as waterproofing, LED lighting, and Bluetooth tracking. Furthermore, the company supports small-batch customization and mixed-style production, with a minimum order quantity (MOQ) of only 500 pieces per style, meeting the flexible procurement needs of different clients. This model is suitable not only for OEM/ODM cooperation but also for developing independent brands and expanding into differentiated markets.

1. Intelligent and Modular Upgrades: Integrating LED lighting, Bluetooth positioning, anti-theft locks, and detachable compartments improves operational efficiency and mobility.

2. Lightweight and Ergonomic Optimization: The use of high-strength nylon, TPU base plates, and PU wheels makes the backpack lightweight and durable, while optimized shoulder straps, back panels, and pull rod designs enhance comfort during extended carrying.

3. Environmentally Friendly and Sustainable Material Applications: Utilizing RPET recycled fabric and biodegradable nylon, the backpack meets international procurement standards and green manufacturing trends.

4. Cross-industry expansion and brand development: From professional fields such as electrical engineering, plumbing, and auto repair, Chinese companies are expanding into security, logistics, landscaping, and outdoor operations. Market demands are becoming increasingly diversified, and Chinese companies are enhancing their international competitiveness through independent brands and customized services.

English

English  español

español