Product Definition and Design Features

The molded base tool backpack is a highly durable backpack specifically designed to carry various hand and power tools. Its bottom features a molded structure, molded from a single piece of high-strength plastic or composite material. This design combines the backpack's flexibility with the protective performance of a hard base, making it convenient for shoulder carrying while maintaining structural stability under frequent movement and heavy loads.

The plastic base provides waterproof, moisture-proof, and stain-resistant properties, ensuring the backpack remains stable and upright even in harsh environments such as mud, wetness, and gravel, protecting internal tools from damage. This bottom structure not only enhances durability but also significantly improves the backpack's reliability under prolonged heavy loads and frequent movement, making it particularly suitable for construction sites, outdoor maintenance, and professional operation scenarios.

In terms of internal design, the molded base tool backpack typically employs a multi-layered, compartmentalized structure with rationally distributed internal dividers, capable of simultaneously accommodating multiple hand and power tools such as drills, screwdrivers, and wrenches. Furthermore, the backpack is equipped with thick shoulder straps and a breathable back panel to reduce shoulder and back pressure and improve comfort during extended work sessions. Modern design features optimized waterproof zippers, abrasion-resistant fabrics, and tear-resistant stitching, ensuring the backpack is both sturdy and portable.

Application Scenarios and Market Demand

The molded base tool backpack, with its rigid base design and functional internal layout, demonstrates unique advantages in various professional work scenarios:

Professional Construction and Industrial Applications: In construction, renovation, and ground work, workers need to carry heavy and diverse tools. The molded base design ensures the backpack maintains its shape during frequent placement and handling, while the abrasion-resistant, pressure-resistant, waterproof, and stain-resistant bottom reduces the risk of damage from tool contact with the ground. Simultaneously, the well-organized multi-layered compartments improve tool classification and management efficiency, making on-site operations more efficient.

Electrical and Mechanical Engineering: Electricians and mechanical maintenance personnel often work in diverse environments, using a variety of tools with high requirements for moisture and shock resistance. The molded base tool backpack provides a sturdy base and protective performance, protecting precision instruments and power tools from impact damage. The compartmentalized design facilitates quick tool access, greatly improving work efficiency.

Outdoor Maintenance and Emergency Operations: In plumbing, electrical installations, pipe maintenance, landscaping, and other outdoor maintenance tasks, backpacks often need to be placed directly on muddy or wet ground. The molded bottom design ensures the backpack stands stably, while its waterproof, moisture-proof, and stain-resistant properties ensure tools remain dry and safe, adapting to complex outdoor environments. Thick shoulder straps and a breathable back panel reduce the burden of prolonged carrying, allowing workers to work comfortably.

Home DIY and Hobby Market: With the development of DIY culture, home users and hobbyists have increasingly higher requirements for tool storage and portability. The rigid bottom design of the molded base backpack allows for stable storage, and its categorized compartments can hold various power and hand tools, facilitating home renovations, gardening, furniture assembly, and other operations.

In terms of market demand, with the development of the construction industry, the increase in outdoor repair activities, and the popularization of DIY culture, the demand for molded base tool backpacks continues to grow. Key user concerns include load-bearing capacity, bottom sturdiness, waterproofing and stain resistance, tool organization, comfort, and durability. These factors directly drive technological upgrades and functional innovations in the industry.

Industry Trends and Development Prospects

The future development of the molded base tool backpack industry is not only reflected in material innovation, functional diversification, and lightweight design, but also in the transformation of manufacturing enterprises towards customized solutions and efficient production capabilities. Under this trend, the practices of Yancheng Tengchi Tourism Products Co., Ltd. provide industry reference.

Modern users have placed multi-dimensional demands on tool backpacks, including load-bearing capacity, waterproofing and stain resistance, tool classification and management, comfort, and durability. At the same time, different industries and work scenarios have differentiated needs for backpack functionality. The molded base design ensures the stability of tools under frequent movement or heavy loads, while multi-layered partitions and a reasonable internal layout meet the needs of classified storage of different tools. Yancheng Tengchi Tourism Products Co., Ltd., through its professional engineering team, combines the client's brand image and product characteristics to provide personalized customization services for global brands, achieving integrated solutions from design concept to engineering optimization to mass production. Its "collaborative development" model can optimize client design sketches into high-quality products, enabling backpacks to reach industry-leading levels in functionality, durability, and ergonomic comfort. Yancheng Tengchi Tourism Products Co., Ltd. owns a 25,000-square-meter factory with four professional production lines and over 130 professional employees, enabling rapid prototyping and prototype production within 7-10 days. The company independently controls the production process, ensuring that every detail of each tool backpack meets high quality standards. This self-controlled production capability gives it a significant advantage in meeting the rapid product iteration needs of global brand clients. It also supports small-batch customization and mixed-style production, with a minimum order quantity of only 500 pieces per style, providing flexible solutions for small and medium-sized brands and professional clients.

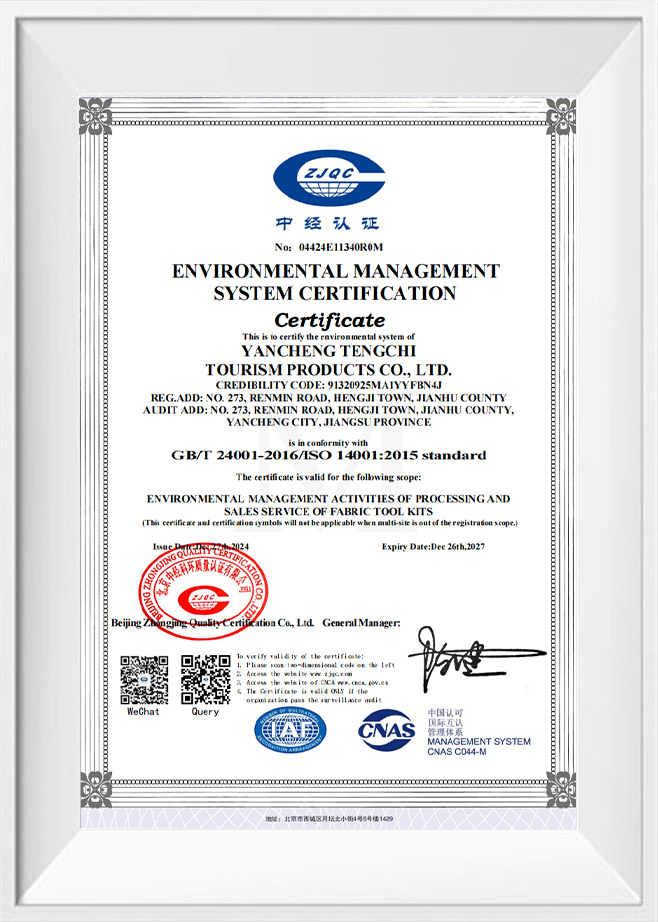

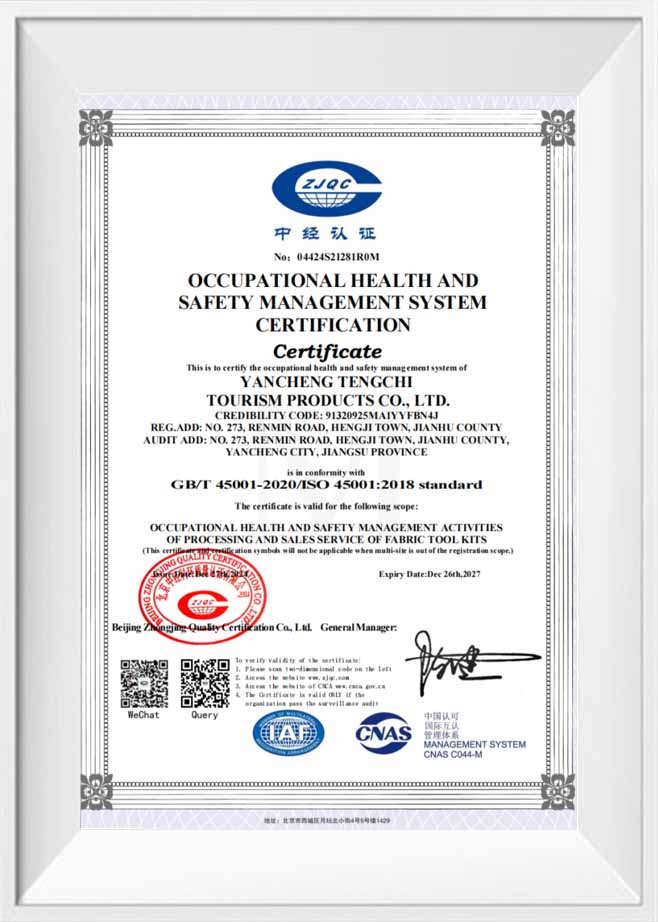

The bottom material of the molded backpack needs to balance load-bearing capacity, abrasion resistance, waterproofing, stain resistance, and lightweight properties. Yancheng Tengchi Tourism Products Co., Ltd. can provide professional solutions for material selection and processes according to customer needs, ensuring that products meet international standards such as ISO certification and RoHS environmental requirements. This not only meets the global market's requirements for environmental and safety standards but also provides a differentiated competitive advantage in the high-end market.

The demand for molded base tool backpacks continues to grow in the industrial, construction, electrical, outdoor work, and home DIY markets. Combining Yancheng Tengchi Tourism Products Co., Ltd.'s end-to-end customization services, rapid prototyping capabilities, and high-standard production management, brand clients can quickly launch high-performance tool backpacks that meet the standards and market demands of different regions, thereby enhancing their market competitiveness. In the next five to ten years, the molded base tool backpack industry will exhibit trends towards functional diversification, specialization, customization, and environmental friendliness. Companies like Yancheng Tengchi Tourism Products Co., Ltd., with their rapid response capabilities, customized service capabilities, and self-controlled production capabilities, will become a significant force driving innovation and raising market standards within the industry.

English

English  español

español